Ford Celebrates a Century in South Africa – A Legacy of Firsts Spanning 100 Years

2023-09-28

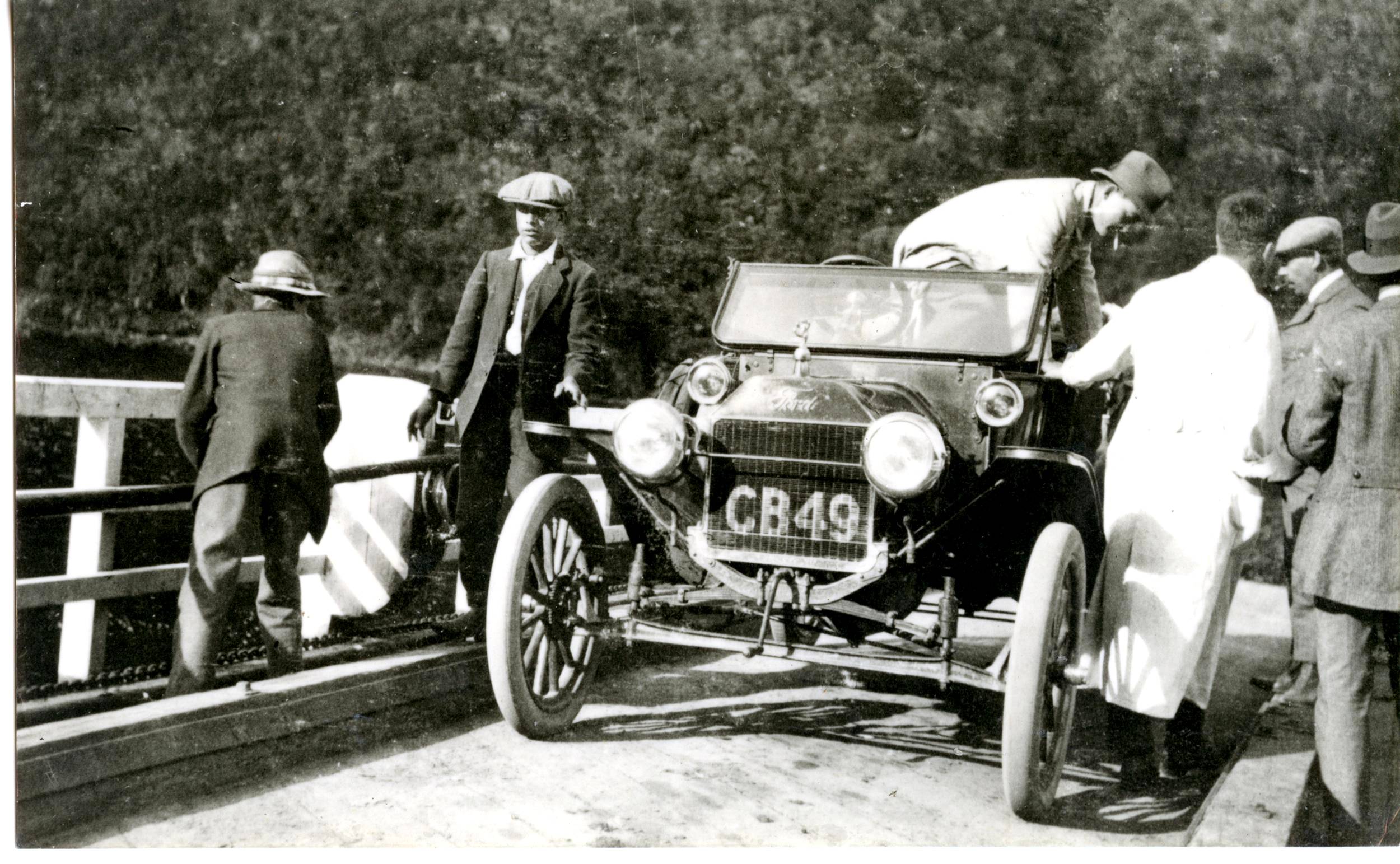

Source: QuickpicThe iconic Model T brought Ford’s meteoric rise, introducing the pioneering assembly line in 1913 and producing 9 000 vehicles a day by the 1920s

Ford’s legacy in South Africa spans a century, playing a vital role in the country’s history since 1923

In today’s fast-paced, interconnected world, it’s almost impossible to envision life a century ago without the modern conveniences we now take for granted, such as computers, high-speed internet, smartphones, air travel, and automobiles, which are so fundamental to everything we do. Ford has played an integral role in South Africa’s history since establishing its local operations in 1923, boasting a proud tradition of pioneering achievements and industry milestones over the past century.

In 1903, the same year as the Wright brothers’ ground-breaking 12-second, 36-metre powered flight at Kitty Hawk in North Carolina, intrepid engineer Henry Ford and a team of investors established the Ford Motor Company. Their venture began on 16 June, six months before the Wright Flyer’s historic flight. With a modest capital of just $28 000, the Ford Motor Company embarked on its journey.

Signalling South Africa’s importance within the company’s global ambitions, Henry Ford made a strategic move just two years later. He appointed Arkell & Douglas in Port Elizabeth as the company’s agents in the country for the distribution and sale of Ford cars within the local market.

While the early Ford models set the wheels in motion, it was the Model T that was responsible for the company’s meteoric rise following its 1908 launch, and it took the world by storm. By the end of the 1920s, Ford Motor Company was churning out an astonishing 9 000 vehicles a day at its plant in Detroit. This achievement was greatly influenced by Henry Ford’s unwavering commitment to making motoring affordable for everyone. Additionally, in 1913, the company introduced the automotive industry’s pioneering moving assembly line, significantly reducing the time it took to build a vehicle from around 12 hours to just 90 minutes.

To meet the immense global demand for the Model T, Ford began building plants outside of the United States, and established Ford of Canada which supplied vehicles to the British Commonwealth markets, including South Africa. The Model T quickly became SA’s most popular car, and it was only a matter of time before the decision was made to begin assembling vehicles in South Africa.

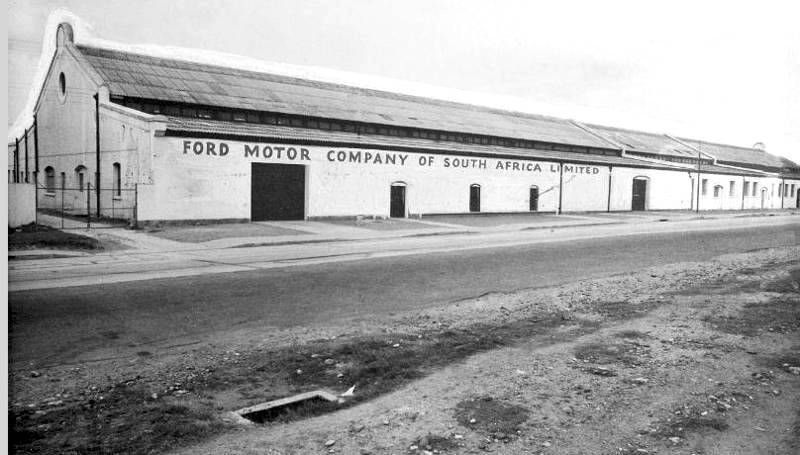

In November 1923, Ford Motor Company of South Africa was founded in Port Elizabeth (now Gqeberha). It operated as a subsidiary of Ford of Canada, strategically leveraging the city’s well-established sea, rail and road links. Work began immediately on converting an old wool store in Grahamstown Road. This transformation marked the inception of Ford’s 16th assembly plant outside of the US. The local assembly operations began with the Model T, utilising completely knocked-down (CKD) kits imported from Canada. This pioneering move not only made Ford the first global vehicle manufacturer to establish operations in South Africa, but also introduced the continent’s initial assembly line of any kind.

Assembly operations began on 19 January 1924 at a planned rate of 10 cars per day, and the first locally produced models went on sale in March that year. The company had 21 office staff along with 70 people in the assembly plant, and it turned out 1 446 vehicles in the first 12 months. Affordability remained key to Ford’s success, with advertisements from 1924 offering five-seater touring cars (with a self-starter and ‘fully equipped’) available from £165, light delivery vans from £145, and a one-ton truck at just £150.

Ford dominated the SA market during those fascinating formative years, with government records at the end of 1925 reflecting 18 118 licensed Fords in the country, which was nearly three times its nearest competitor. By the end of 1926, Ford began offering its vehicles in colours beyond the archetypal black, including options like ‘deep mole’ and ‘dark green’. During that year the plant produced a combined total of 2 069 cars and 1 093 trucks.

Model T production concluded in 1927, with an astonishing 15 million units manufactured worldwide. It’s no surprise that this iconic car was selected as the Car of the Century by an international jury of motoring journalists and industry experts in 1999, as it played a pivotal role in making automobiles accessible to the masses.

Ford soon outgrew the old wool store in Port Elizabeth. In October 1930 Ford Motor Company of South Africa relocated to a new factory in Harrower Road, spanning 7 032m2 and costing R1 110 503 at the time. Initially, the factory began producing the Model A at a rate of 90 vehicles per day.

In September 1935, the National Association of Automobile Manufacturers of South Africa (NAAMSA) was established with Ford as a founding member, and nearly nine decades later the organisation remains a cornerstone of the industry.

Over the following years, Ford’s Harrower Road facility underwent multiple expansions, reaching a size of 14 896m2 under a single roof by 1937. It was supplemented by an additional factory covering another 7 056m2 two years later, and by 1940 the floor space had increased to 24 112m2.

During World War II, the majority of the country’s manufacturing capacity was redirected to support the Allied campaign. The Ford plant played a significant role, producing almost 60 000 vehicles between 1939 and 1945, with 36 339 vehicles going to the Union Defence Force alone. Interestingly, one of the most important tasks carried out by Ford during this period was for the South African Air Force, specifically the repair of wings for Anson training aircraft. Post-war production resumed in June 1946, and Ford assembled 3 446 cars and 2 005 trucks during the second half of the year.

By 1947, Ford ramped up its expansion yet again, as construction began on a new plant in the Neave Industrial Township. The new R2-million facility officially opened on 1 October 1948. It provided employment for 1 100 people and occupied 50 000m2 of the 200 000m2 site. Notably, this facility became the largest plant under one roof in South Africa and boasted the largest window in Africa – a staggering 354 metres in length and seven metres in height.

In 1954, a modern administration block was incorporated into the plant at a cost of R1-million. The Neave plant was responsible for producing an extensive range of memorable cars such as the Fairlane, Zephyr, Zodiac, Anglia, Prefect, Consul, Escort, Granada, and the legendary two-door Capri. It also assembled Ford’s range of Thames and Louisville trucks and Fordson Major diesel tractors, with the passenger and commercial vehicles sold locally and exported across Sub-Saharan Africa.

Remarkably, all three of these early Ford plants, including the original wool store, are still standing today, albeit repurposed and sold to new owners over the years.

Expansion and progress

During the 1960s Ford made significant investments in the domestic automotive sector, announcing a R4-million expansion initiative in 1962. This involved the construction of a Parts and Accessories Warehouse in Struandale, an extension of the Neave plant to accommodate an engine assembly line, and the development of a new test track.

Then, in October 1963, Ford announced a landmark R8-million investment in a dedicated engine manufacturing facility. The Struandale Engine Plant was officially opened by Henry Ford II in May 1964, making it the first motor company in South Africa to manufacture engines locally for passenger cars and trucks. The new plant employed 300 people and production commenced with the legendary 3.0-litre Essex V6 engine, which would became synonymous with fast Fords in the ensuing decades. Additionally, the plant produced the 1.7L and 2.0L V4 engines, as well as the robust 1.3L and 1.6L Kent OHV engines.

Ford’s extensive local testing, research and development was given a significant boost in 1966 when it purchased a 3 400-acre site, known as the farm Rietkuil, alongside the small St Alban’s Airport west of Port Elizabeth. A R2-million proving ground was built incorporating four test tracks of varying surfaces. In 1968, a purpose-designed Product Development and Engineering facility was established, which became the breeding ground for many local developments that were unique to South Africa. These included various iterations of the Cortina bakkie (pickup), and the Bantam bakkie introduced in 1983, which was the first vehicle to win the prestigious Shell Design Award.

In the 1960s and ’70s, the booming automotive industry prompted Ford to invest R9.25-million in a Struandale Assembly Plant, situated adjacent to the engine facility. This plant, specifically designed for Cortina production, commenced operations in 1973, boasting an initial production capacity of 110 units per day and employing almost 1 200 people. Production of the Cortina continued until 1983, with more than 303 000 units sold in South Africa. Ford also operated a truck plant in Deal Party Estate, which did final assembly of its rugged D-Series and F-Series trucks using parts supplied from the Neave plant.

In 1976 Ford Motor Company of South Africa produced its one-millionth vehicle, affirming its continued status as one of the most significant players in the local automotive industry. With Port Elizabeth being the hub of the thriving vehicle manufacturing sector since the 1920s, it was commonly referred to as the Detroit of South Africa.

Political turmoil and local innovation

The political upheaval of the 1980s led to Ford entering negotiations with Amcar (the successor to the Sigma Motor Corporation) and Anglo American. These discussions culminated in the creation of the South African Motor Corporation (SAMCOR) in January 1985, which took over Ford’s local manufacturing, distribution, and sales operations. Ford’s 40-percent stake in SAMCOR was ultimately transferred to a trust, which subsequently allocated a large portion of the shares to its black employees – an unprecedented move at the time.

This move led to all of Ford’s vehicle assembly operations in Port Elizabeth being relocated and consolidated at the SAMCOR plant in Silverton, east of Pretoria. The plant had previously formed part of Sigma, primarily functioning as a Chrysler plant, and then later transitioned into Amcar. The Struandale Engine Plant remained in Port Elizabeth, where it continues today.

Due to strict sanctions and isolation during the Apartheid era, Ford’s local engineers had to devise innovative solutions to keep the model range appealing and competitive. This pioneering culture gave rise to numerous legendary cars that have become highly prized and extremely valuable. These include the Cortina XR6 (including the limited-edition Interceptor and Team Ford – or TF – variants), the Sierra XR6, the later fuel-injected 3.0iRS Sierra and Sapphire models and, of course, the revered and rare Sierra XR8, which was limited to just 250 units and was powered by a Mustang-derived 5.0L V8.

The two-millionth vehicle was produced in 1993. This milestone pre-empted Ford’s imminent return to South Africa. In 1994, Ford acquired a 45-percent equity stake in SAMCOR from Anglo American, a significant move that showcased confidence in the country’s transition to democracy under the leadership of Nelson Mandela.

In 1997, production of the Ford Fiesta commenced at the Silverton Assembly Plant. Just a year later, it earned the prestigious title of South African Car of the Year – the country’s most illustrious motoring award.

100-percent Ford, Ranger to the fore

The year 2000 represented several watershed moments as Ford attained full ownership of SAMCOR, acquiring 100-percent equity. Concurrently, it led to the establishment of the Ford Motor Company of Southern Africa (FMCSA). In that same year, the first-generation Ranger was unveiled, supplanting the Courier and reaffirming Ford’s position as a formidable contender in the light commercial vehicle segment. This marked the inception of the central nameplate that would define so much of the company’s future.

A total of 105 950 Rangers were sold in South Africa between 2000 and 2011, but it was Ford’s major investment in the subsequent model that really pivoted the local operations on to the global stage. The company streamlined its manufacturing portfolio, shifting away from diverse, low-volume products and brands to concentrate solely on the Ranger platform.

In 2010, Ford confirmed a massive R3.4-billion investment in South Africa for its global export programme. This initiative included the production of the new Ranger at the Silverton Assembly Plant and the component machining and assembly of the 2.2L and 3.2L Duratorq TDCi engines at the Struandale Engine Plant. The investment effectively more than doubled Ford’s local manufacturing capacity to 110 000 vehicles per year.

The new Ranger set completely new benchmarks for design, comfort, luxury, performance and safety. Notably, it marked another pioneering achievement for Ford by becoming the first pickup in history to achieve the coveted 5-Star Euro NCAP safety rating.

The three-millionth vehicle was produced in 2013. This historic moment was commemorated during a memorable visit to the country by then Ford Motor Company president and CEO, Alan Mulally.

By 2018, Ford had invested R11-billion in the export-driven programme, with installed production capacity climbing to 168 000 vehicles per year. These investments included local manufacturing of the Everest SUV from 2016, significant updates to the local operations for producing the first-ever Ranger Raptor, and the installation of a new assembly line for the latest-generation 2.0L Single Turbo and Bi-Turbo diesel engines at the Struandale plant.

As they say in the classics, that’s not all folks… Actually, far from it. In 2019, Ford embarked on a pioneering public-private partnership with national, local and provincial government entities to establish the Tshwane Automotive Special Economic Zone. This innovative supplier hub, located next to the Silverton plant, was the first of its kind in South Africa.

This laid the groundwork for creating thousands of job opportunities for surrounding communities, while playing a central role in Ford’s ability to significantly ramp up its production capacity. In 2021, Ford Motor Company invested an astonishing R16.8-billion to modernise and significantly expand its Silverton operations for the Next-Gen Ranger.

As the largest single investment in the automotive industry to date, this funding facilitated the complete overhaul of the Silverton Assembly Plant, incorporating state-of-the-art production technologies. It also led to the construction of Ford’s first on-site Stamping Plant, a high-tech new Body Shop, and the world’s only Ford-owned and operated Chassis Plant. In addition, this investment covered the latest tooling for Ford’s supplier companies. Crucially, this increased the installed capacity to 200 000 vehicles annually and created an additional 1 200 permanent jobs at the Silverton plant, bringing Ford’s workforce in South Africa to 5 500 employees. And Ford continues to make further incremental investments to enhance both vehicle quality and the working environment for its employees.

In 2022, the Silverton Assembly Plant also took a major step towards sustainability and relying increasingly on renewable energy when it switched on a pioneering solar-energy project. Solar photovoltaic carports for 3 610 vehicles were installed at the plant, making it one of the largest solar PV carport installations in the world. With a total output of 13.5MW, this generates around 35 percent of the facility’s electricity requirements.

Furthermore, an additional R600-million was invested in the Struandale Engine Plant to introduce a third diesel engine programme, featuring the new 3.0L V6 that would become the headline act in the locally produced new Ranger line-up. Yet again, creative thinking by the local team saw the existing Duratorq TDCi assembly line being upgraded and expanded to accommodate the 3.0L V6 Diesel while maintaining production of the existing engines. This unique setup makes it the only Ford engine assembly line globally capable of producing in-line and V-configuration engines, along with a combination of four, five and six-cylinder units, all on the same line.

This ingenuity played a key role in the Struandale Engine Plant securing its first overall Exporter of the Year title from Exporters Eastern Cape in 2022, along with its fifth Best Exporter OEM award. And, to add more feathers in Ford’s cap, in August 2023 the Struandale plant reached the remarkable milestone of producing its four-millionth engine to date covering 11 different engine types. Additionally, it marked the production of the 300 000th 2.0L SiT/BiT diesel engine since the programme’s launch in 2018.

Winning formula

And the laurels keep coming… This year the new Ranger made history by becoming the first bakkie to win the prestigious South African Car of the Year title. Moreover, its sibling, the Everest SUV, not only secured the Adventure SUV crown for 2023 but also finished second overall, to the Ranger.

Demand for the proudly South African-built Ranger continues to soar, far outstripping supply. This holds true not only within the local market but also in more than 100 international markets that receive shipments of this vehicle from South Africa. With the Silverton plant designed to produce 720 vehicles per day over three shifts, the team has exceeded that target on numerous occasions. On 8 August this year 736 vehicles emerged from the plant in 24 hours. Just three days later, the team went one better – quite literally – to bump that figure to 737 units. This achievement not only set a record for the Silverton Assembly Plant, but more importantly for the South African automotive manufacturing industry too.

As Ford builds up to its Centenary celebrations later this year, it provides a moment to pause and reflect on a truly remarkable history. This history includes a long list of iconic nameplates that have provided people with mobility for 100 years. It’s an opportunity to acknowledge the bold steps taken to reach new heights and to highlight the significant industry firsts and records that have been set along the way.

But beyond the products, the buildings, the more than R30-billion invested in the past 13 years, and the extensive list of accolades, it is the people who have defined the brand and its legacy that truly matter. This includes generations of family members who have spent their entire careers at Ford, the dealers who have been the face of the brand for decades, the loyal customers who have blue blood flowing through their veins, and the numerous communities and individuals who have been empowered by Ford’s far-reaching employment opportunities and uplifted through its wide-ranging corporate responsibility initiatives.

Looking back is of great value and importance as it sets the tone for the future. Undoubtedly, there are many more interesting and exciting chapters still to be written as the Blue Oval embarks on bold steps into the next century.

In 1903, the same year as the Wright brothers’ ground-breaking 12-second, 36-metre powered flight at Kitty Hawk in North Carolina, intrepid engineer Henry Ford and a team of investors established the Ford Motor Company. Their venture began on 16 June, six months before the Wright Flyer’s historic flight. With a modest capital of just $28 000, the Ford Motor Company embarked on its journey.

Signalling South Africa’s importance within the company’s global ambitions, Henry Ford made a strategic move just two years later. He appointed Arkell & Douglas in Port Elizabeth as the company’s agents in the country for the distribution and sale of Ford cars within the local market.

While the early Ford models set the wheels in motion, it was the Model T that was responsible for the company’s meteoric rise following its 1908 launch, and it took the world by storm. By the end of the 1920s, Ford Motor Company was churning out an astonishing 9 000 vehicles a day at its plant in Detroit. This achievement was greatly influenced by Henry Ford’s unwavering commitment to making motoring affordable for everyone. Additionally, in 1913, the company introduced the automotive industry’s pioneering moving assembly line, significantly reducing the time it took to build a vehicle from around 12 hours to just 90 minutes.

To meet the immense global demand for the Model T, Ford began building plants outside of the United States, and established Ford of Canada which supplied vehicles to the British Commonwealth markets, including South Africa. The Model T quickly became SA’s most popular car, and it was only a matter of time before the decision was made to begin assembling vehicles in South Africa.

In November 1923, Ford Motor Company of South Africa was founded in Port Elizabeth (now Gqeberha). It operated as a subsidiary of Ford of Canada, strategically leveraging the city’s well-established sea, rail and road links. Work began immediately on converting an old wool store in Grahamstown Road. This transformation marked the inception of Ford’s 16th assembly plant outside of the US. The local assembly operations began with the Model T, utilising completely knocked-down (CKD) kits imported from Canada. This pioneering move not only made Ford the first global vehicle manufacturer to establish operations in South Africa, but also introduced the continent’s initial assembly line of any kind.

Assembly operations began on 19 January 1924 at a planned rate of 10 cars per day, and the first locally produced models went on sale in March that year. The company had 21 office staff along with 70 people in the assembly plant, and it turned out 1 446 vehicles in the first 12 months. Affordability remained key to Ford’s success, with advertisements from 1924 offering five-seater touring cars (with a self-starter and ‘fully equipped’) available from £165, light delivery vans from £145, and a one-ton truck at just £150.

Ford dominated the SA market during those fascinating formative years, with government records at the end of 1925 reflecting 18 118 licensed Fords in the country, which was nearly three times its nearest competitor. By the end of 1926, Ford began offering its vehicles in colours beyond the archetypal black, including options like ‘deep mole’ and ‘dark green’. During that year the plant produced a combined total of 2 069 cars and 1 093 trucks.

Model T production concluded in 1927, with an astonishing 15 million units manufactured worldwide. It’s no surprise that this iconic car was selected as the Car of the Century by an international jury of motoring journalists and industry experts in 1999, as it played a pivotal role in making automobiles accessible to the masses.

Ford soon outgrew the old wool store in Port Elizabeth. In October 1930 Ford Motor Company of South Africa relocated to a new factory in Harrower Road, spanning 7 032m2 and costing R1 110 503 at the time. Initially, the factory began producing the Model A at a rate of 90 vehicles per day.

In September 1935, the National Association of Automobile Manufacturers of South Africa (NAAMSA) was established with Ford as a founding member, and nearly nine decades later the organisation remains a cornerstone of the industry.

Over the following years, Ford’s Harrower Road facility underwent multiple expansions, reaching a size of 14 896m2 under a single roof by 1937. It was supplemented by an additional factory covering another 7 056m2 two years later, and by 1940 the floor space had increased to 24 112m2.

During World War II, the majority of the country’s manufacturing capacity was redirected to support the Allied campaign. The Ford plant played a significant role, producing almost 60 000 vehicles between 1939 and 1945, with 36 339 vehicles going to the Union Defence Force alone. Interestingly, one of the most important tasks carried out by Ford during this period was for the South African Air Force, specifically the repair of wings for Anson training aircraft. Post-war production resumed in June 1946, and Ford assembled 3 446 cars and 2 005 trucks during the second half of the year.

By 1947, Ford ramped up its expansion yet again, as construction began on a new plant in the Neave Industrial Township. The new R2-million facility officially opened on 1 October 1948. It provided employment for 1 100 people and occupied 50 000m2 of the 200 000m2 site. Notably, this facility became the largest plant under one roof in South Africa and boasted the largest window in Africa – a staggering 354 metres in length and seven metres in height.

In 1954, a modern administration block was incorporated into the plant at a cost of R1-million. The Neave plant was responsible for producing an extensive range of memorable cars such as the Fairlane, Zephyr, Zodiac, Anglia, Prefect, Consul, Escort, Granada, and the legendary two-door Capri. It also assembled Ford’s range of Thames and Louisville trucks and Fordson Major diesel tractors, with the passenger and commercial vehicles sold locally and exported across Sub-Saharan Africa.

Remarkably, all three of these early Ford plants, including the original wool store, are still standing today, albeit repurposed and sold to new owners over the years.

Expansion and progress

During the 1960s Ford made significant investments in the domestic automotive sector, announcing a R4-million expansion initiative in 1962. This involved the construction of a Parts and Accessories Warehouse in Struandale, an extension of the Neave plant to accommodate an engine assembly line, and the development of a new test track.

Then, in October 1963, Ford announced a landmark R8-million investment in a dedicated engine manufacturing facility. The Struandale Engine Plant was officially opened by Henry Ford II in May 1964, making it the first motor company in South Africa to manufacture engines locally for passenger cars and trucks. The new plant employed 300 people and production commenced with the legendary 3.0-litre Essex V6 engine, which would became synonymous with fast Fords in the ensuing decades. Additionally, the plant produced the 1.7L and 2.0L V4 engines, as well as the robust 1.3L and 1.6L Kent OHV engines.

Ford’s extensive local testing, research and development was given a significant boost in 1966 when it purchased a 3 400-acre site, known as the farm Rietkuil, alongside the small St Alban’s Airport west of Port Elizabeth. A R2-million proving ground was built incorporating four test tracks of varying surfaces. In 1968, a purpose-designed Product Development and Engineering facility was established, which became the breeding ground for many local developments that were unique to South Africa. These included various iterations of the Cortina bakkie (pickup), and the Bantam bakkie introduced in 1983, which was the first vehicle to win the prestigious Shell Design Award.

In the 1960s and ’70s, the booming automotive industry prompted Ford to invest R9.25-million in a Struandale Assembly Plant, situated adjacent to the engine facility. This plant, specifically designed for Cortina production, commenced operations in 1973, boasting an initial production capacity of 110 units per day and employing almost 1 200 people. Production of the Cortina continued until 1983, with more than 303 000 units sold in South Africa. Ford also operated a truck plant in Deal Party Estate, which did final assembly of its rugged D-Series and F-Series trucks using parts supplied from the Neave plant.

In 1976 Ford Motor Company of South Africa produced its one-millionth vehicle, affirming its continued status as one of the most significant players in the local automotive industry. With Port Elizabeth being the hub of the thriving vehicle manufacturing sector since the 1920s, it was commonly referred to as the Detroit of South Africa.

Political turmoil and local innovation

The political upheaval of the 1980s led to Ford entering negotiations with Amcar (the successor to the Sigma Motor Corporation) and Anglo American. These discussions culminated in the creation of the South African Motor Corporation (SAMCOR) in January 1985, which took over Ford’s local manufacturing, distribution, and sales operations. Ford’s 40-percent stake in SAMCOR was ultimately transferred to a trust, which subsequently allocated a large portion of the shares to its black employees – an unprecedented move at the time.

This move led to all of Ford’s vehicle assembly operations in Port Elizabeth being relocated and consolidated at the SAMCOR plant in Silverton, east of Pretoria. The plant had previously formed part of Sigma, primarily functioning as a Chrysler plant, and then later transitioned into Amcar. The Struandale Engine Plant remained in Port Elizabeth, where it continues today.

Due to strict sanctions and isolation during the Apartheid era, Ford’s local engineers had to devise innovative solutions to keep the model range appealing and competitive. This pioneering culture gave rise to numerous legendary cars that have become highly prized and extremely valuable. These include the Cortina XR6 (including the limited-edition Interceptor and Team Ford – or TF – variants), the Sierra XR6, the later fuel-injected 3.0iRS Sierra and Sapphire models and, of course, the revered and rare Sierra XR8, which was limited to just 250 units and was powered by a Mustang-derived 5.0L V8.

The two-millionth vehicle was produced in 1993. This milestone pre-empted Ford’s imminent return to South Africa. In 1994, Ford acquired a 45-percent equity stake in SAMCOR from Anglo American, a significant move that showcased confidence in the country’s transition to democracy under the leadership of Nelson Mandela.

In 1997, production of the Ford Fiesta commenced at the Silverton Assembly Plant. Just a year later, it earned the prestigious title of South African Car of the Year – the country’s most illustrious motoring award.

100-percent Ford, Ranger to the fore

The year 2000 represented several watershed moments as Ford attained full ownership of SAMCOR, acquiring 100-percent equity. Concurrently, it led to the establishment of the Ford Motor Company of Southern Africa (FMCSA). In that same year, the first-generation Ranger was unveiled, supplanting the Courier and reaffirming Ford’s position as a formidable contender in the light commercial vehicle segment. This marked the inception of the central nameplate that would define so much of the company’s future.

A total of 105 950 Rangers were sold in South Africa between 2000 and 2011, but it was Ford’s major investment in the subsequent model that really pivoted the local operations on to the global stage. The company streamlined its manufacturing portfolio, shifting away from diverse, low-volume products and brands to concentrate solely on the Ranger platform.

In 2010, Ford confirmed a massive R3.4-billion investment in South Africa for its global export programme. This initiative included the production of the new Ranger at the Silverton Assembly Plant and the component machining and assembly of the 2.2L and 3.2L Duratorq TDCi engines at the Struandale Engine Plant. The investment effectively more than doubled Ford’s local manufacturing capacity to 110 000 vehicles per year.

The new Ranger set completely new benchmarks for design, comfort, luxury, performance and safety. Notably, it marked another pioneering achievement for Ford by becoming the first pickup in history to achieve the coveted 5-Star Euro NCAP safety rating.

The three-millionth vehicle was produced in 2013. This historic moment was commemorated during a memorable visit to the country by then Ford Motor Company president and CEO, Alan Mulally.

By 2018, Ford had invested R11-billion in the export-driven programme, with installed production capacity climbing to 168 000 vehicles per year. These investments included local manufacturing of the Everest SUV from 2016, significant updates to the local operations for producing the first-ever Ranger Raptor, and the installation of a new assembly line for the latest-generation 2.0L Single Turbo and Bi-Turbo diesel engines at the Struandale plant.

As they say in the classics, that’s not all folks… Actually, far from it. In 2019, Ford embarked on a pioneering public-private partnership with national, local and provincial government entities to establish the Tshwane Automotive Special Economic Zone. This innovative supplier hub, located next to the Silverton plant, was the first of its kind in South Africa.

This laid the groundwork for creating thousands of job opportunities for surrounding communities, while playing a central role in Ford’s ability to significantly ramp up its production capacity. In 2021, Ford Motor Company invested an astonishing R16.8-billion to modernise and significantly expand its Silverton operations for the Next-Gen Ranger.

As the largest single investment in the automotive industry to date, this funding facilitated the complete overhaul of the Silverton Assembly Plant, incorporating state-of-the-art production technologies. It also led to the construction of Ford’s first on-site Stamping Plant, a high-tech new Body Shop, and the world’s only Ford-owned and operated Chassis Plant. In addition, this investment covered the latest tooling for Ford’s supplier companies. Crucially, this increased the installed capacity to 200 000 vehicles annually and created an additional 1 200 permanent jobs at the Silverton plant, bringing Ford’s workforce in South Africa to 5 500 employees. And Ford continues to make further incremental investments to enhance both vehicle quality and the working environment for its employees.

In 2022, the Silverton Assembly Plant also took a major step towards sustainability and relying increasingly on renewable energy when it switched on a pioneering solar-energy project. Solar photovoltaic carports for 3 610 vehicles were installed at the plant, making it one of the largest solar PV carport installations in the world. With a total output of 13.5MW, this generates around 35 percent of the facility’s electricity requirements.

Furthermore, an additional R600-million was invested in the Struandale Engine Plant to introduce a third diesel engine programme, featuring the new 3.0L V6 that would become the headline act in the locally produced new Ranger line-up. Yet again, creative thinking by the local team saw the existing Duratorq TDCi assembly line being upgraded and expanded to accommodate the 3.0L V6 Diesel while maintaining production of the existing engines. This unique setup makes it the only Ford engine assembly line globally capable of producing in-line and V-configuration engines, along with a combination of four, five and six-cylinder units, all on the same line.

This ingenuity played a key role in the Struandale Engine Plant securing its first overall Exporter of the Year title from Exporters Eastern Cape in 2022, along with its fifth Best Exporter OEM award. And, to add more feathers in Ford’s cap, in August 2023 the Struandale plant reached the remarkable milestone of producing its four-millionth engine to date covering 11 different engine types. Additionally, it marked the production of the 300 000th 2.0L SiT/BiT diesel engine since the programme’s launch in 2018.

Winning formula

And the laurels keep coming… This year the new Ranger made history by becoming the first bakkie to win the prestigious South African Car of the Year title. Moreover, its sibling, the Everest SUV, not only secured the Adventure SUV crown for 2023 but also finished second overall, to the Ranger.

Demand for the proudly South African-built Ranger continues to soar, far outstripping supply. This holds true not only within the local market but also in more than 100 international markets that receive shipments of this vehicle from South Africa. With the Silverton plant designed to produce 720 vehicles per day over three shifts, the team has exceeded that target on numerous occasions. On 8 August this year 736 vehicles emerged from the plant in 24 hours. Just three days later, the team went one better – quite literally – to bump that figure to 737 units. This achievement not only set a record for the Silverton Assembly Plant, but more importantly for the South African automotive manufacturing industry too.

As Ford builds up to its Centenary celebrations later this year, it provides a moment to pause and reflect on a truly remarkable history. This history includes a long list of iconic nameplates that have provided people with mobility for 100 years. It’s an opportunity to acknowledge the bold steps taken to reach new heights and to highlight the significant industry firsts and records that have been set along the way.

But beyond the products, the buildings, the more than R30-billion invested in the past 13 years, and the extensive list of accolades, it is the people who have defined the brand and its legacy that truly matter. This includes generations of family members who have spent their entire careers at Ford, the dealers who have been the face of the brand for decades, the loyal customers who have blue blood flowing through their veins, and the numerous communities and individuals who have been empowered by Ford’s far-reaching employment opportunities and uplifted through its wide-ranging corporate responsibility initiatives.

Looking back is of great value and importance as it sets the tone for the future. Undoubtedly, there are many more interesting and exciting chapters still to be written as the Blue Oval embarks on bold steps into the next century.